Imagine the splash of oars, the creaking wood, and the thrill of adventure as we delve into how were Viking longships constructed. These marvels weren’t just boats but lifelines to new worlds for Norse explorers. Crafted with skill and intuition, these vessels sailed through history’s fog.

How were Viking longships constructed? This wasn’t some run-of-the-mill ship building. Vikings used oak mightily in their shipyards to shape hulls rigid enough for serene fjords and stormy North Sea waves.

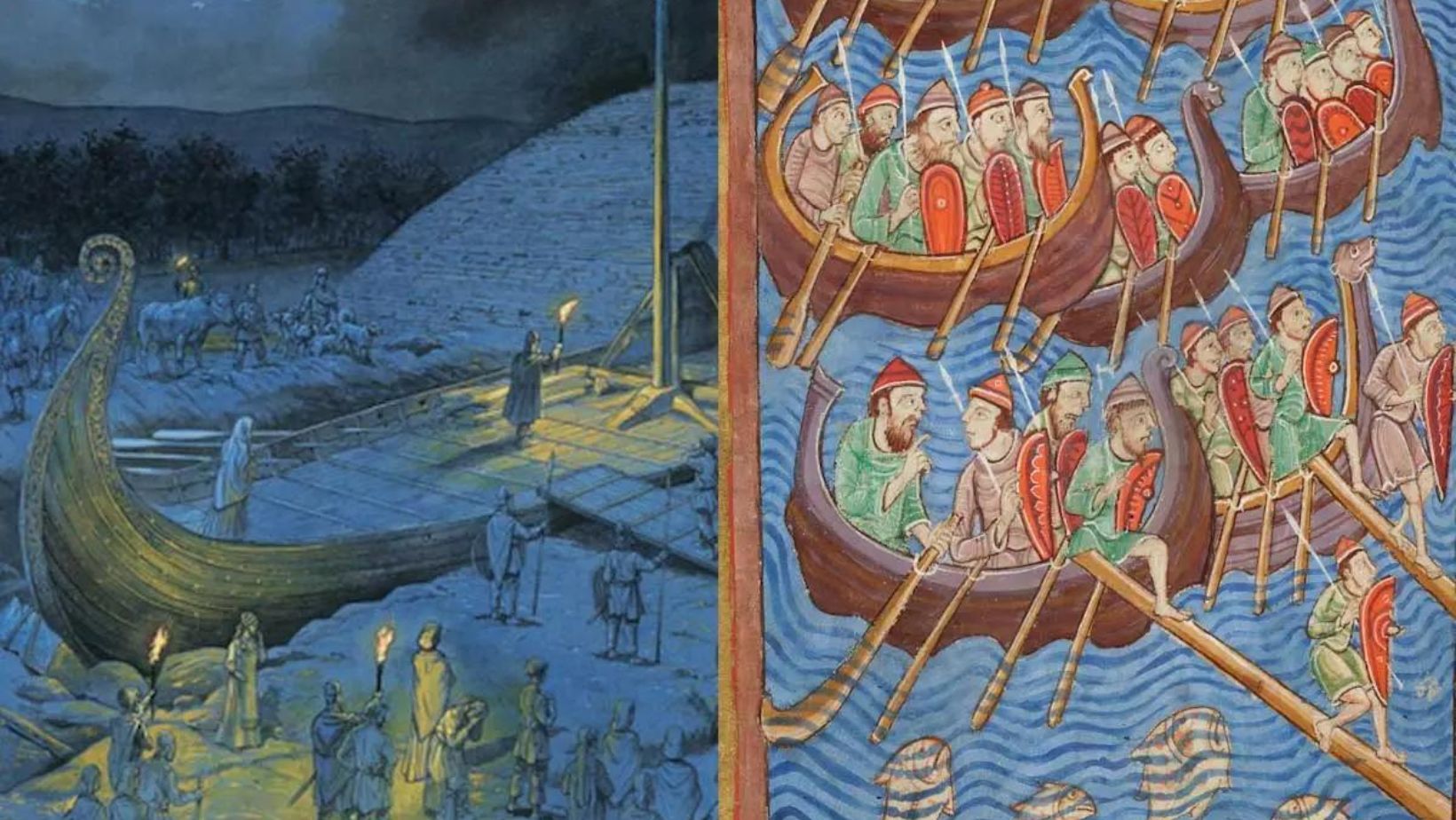

You’re about to step back in time when clinker-built designs ruled, and dragon heads struck awe in every onlooker’s heart. We’ll sail past artistic prows onto seas powered by muscle-bound oarsmen before docking at modern reconstructions that bring sagas back to life.

Table Of Contents:

- The Evolution of Viking Shipbuilding Techniques

- Materials and Tools Used in Crafting Longships

- Anatomy of a Viking Longship

- Crafting Techniques That Defined an Era

- Sailing Mechanics and Maritime Prowess – How Were Viking Longships Constructed?

- Iconography and Cultural Significance

- Preserving History Through Replicas

- Longships’ Role Beyond Warfare – Trade & Exploration

- FAQs in Relation to How Were Viking Longships Constructed

- Conclusion: How Were Viking Longships Constructed?

The Evolution of Viking Shipbuilding Techniques

Viking shipbuilders were the SpaceX engineers of their day, turning sturdy oak into legendary vessels that would make even Poseidon do a double-take. These Viking Age ships weren’t just built; they were engineered with such precision and care it’s like they knew we’d be geeking out over them centuries later.

From Nordic Roots to Viking Mastery

The Vikings didn’t start from scratch—no way. They took the clinker method from earlier Nordic traditions, where you overlap planks like shingles on a roof. Picture this: You’re slicing tree trunks along their fibers, giving you light but strong wooden boards ready for wave-crushing action. This was about more than building skills—it was an art form passed down through generations, culminating in the creation of sleek yet robust longships capable of skimming across shallow waters or facing the North Sea’s worst tantrums.

This wasn’t your weekend DIY project, either. Every piece had its place and purpose—from stern posts that spoke volumes about Norse craftsmanship to hull planks sealed tight with animal hair and tarred wool because who needs leaks when you’re raiding new shores? It’s no wonder these boats became symbols of maritime prowess throughout Northern Europe during what we now call the Viking Age.

Oak’s Endurance at Sea

If Viking longships could talk, they’d boast about being made from nature’s battleship material: oak trees. Not only did these oaks give us oxygen to breathe—but they gave Vikings some serious seafaring muscle, too. Just think—a single tree transforming into part of a majestic sailing ship.

Iron Nails – Holding History Together

And let’s not forget iron nails—the unsung heroes holding everything together while blending so seamlessly into those mighty ships’ aesthetic appeal that one might never know how critical they were in constructing something as grandiose as, say…the Gokstad ship. Without those little pieces of metal toughness connecting each carefully crafted plank—we wouldn’t have much left but soggy firewood after a high-seas adventure.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Viking shipbuilders were master craftsmen who turned oak into iconic ships using the clinker method, ensuring every part was meticulously crafted for durability and performance at sea.

Materials and Tools Used in Crafting Longships

Oak’s Endurance at Sea – How Were Viking Longships Constructed?

Viking shipbuilders were like the master chefs of the sea—instead of pots and pans, they used oak planks to cook up some seriously enduring vessels. These guys knew that oak was more than a pretty tree; it was tough enough to handle whatever the North Sea threw at them. The Vikings weren’t playing around when they chose this timber for their longship construction—it had durability down pat.

Using oak for durability wasn’t just brilliant; it was crucial. It allowed these ships to slice through waves like butter on warm bread while still being able to take a hit or two from unfriendly shores—or other boats looking for trouble. Think about Viking sailors as ancient mariners with nerves (and ships) made of steel before steel became a thing.

Iron Nails – Holding History Together

You know what else is cool? Iron nails. You might not get excited over nails usually, but hear me out—they’re history’s superglue when talking about Viking ships built with precision and skill. With iron fastening hull planks using the clinker method, we have something more substantial than any wood glue at your local hardware store.

The Vikings took ‘nailing it’ quite literally by hammering these bad boys into their iconic longships, ensuring each plank overlapped snugly with its neighbor—a technique known as “clinker-built.” But wait—there’s more. Between those sturdy oak boards went animal hair mixed with tarred wool for waterproofing that would make modern sealants jealous.

Sure, today, you can patch up a leaky boat with all sorts of high-tech stuff, but back then? A blend of nature’s finest fuzzy coats and sticky tar did the trick better than anything else could dream of during those days. This combo didn’t just keep water out; it flexed and moved with the wood, letting Viking ships bob across oceans without prematurely turning into underwater archaeology projects.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Viking shipbuilders rocked the boat-building game with tough oak and iron nails, crafting vessels that could slice through waves yet withstand rough seas. They sealed their ships tight using a clever mix of animal hair and tar—ancient waterproofing that even modern tech would envy.

Anatomy of a Viking Longship

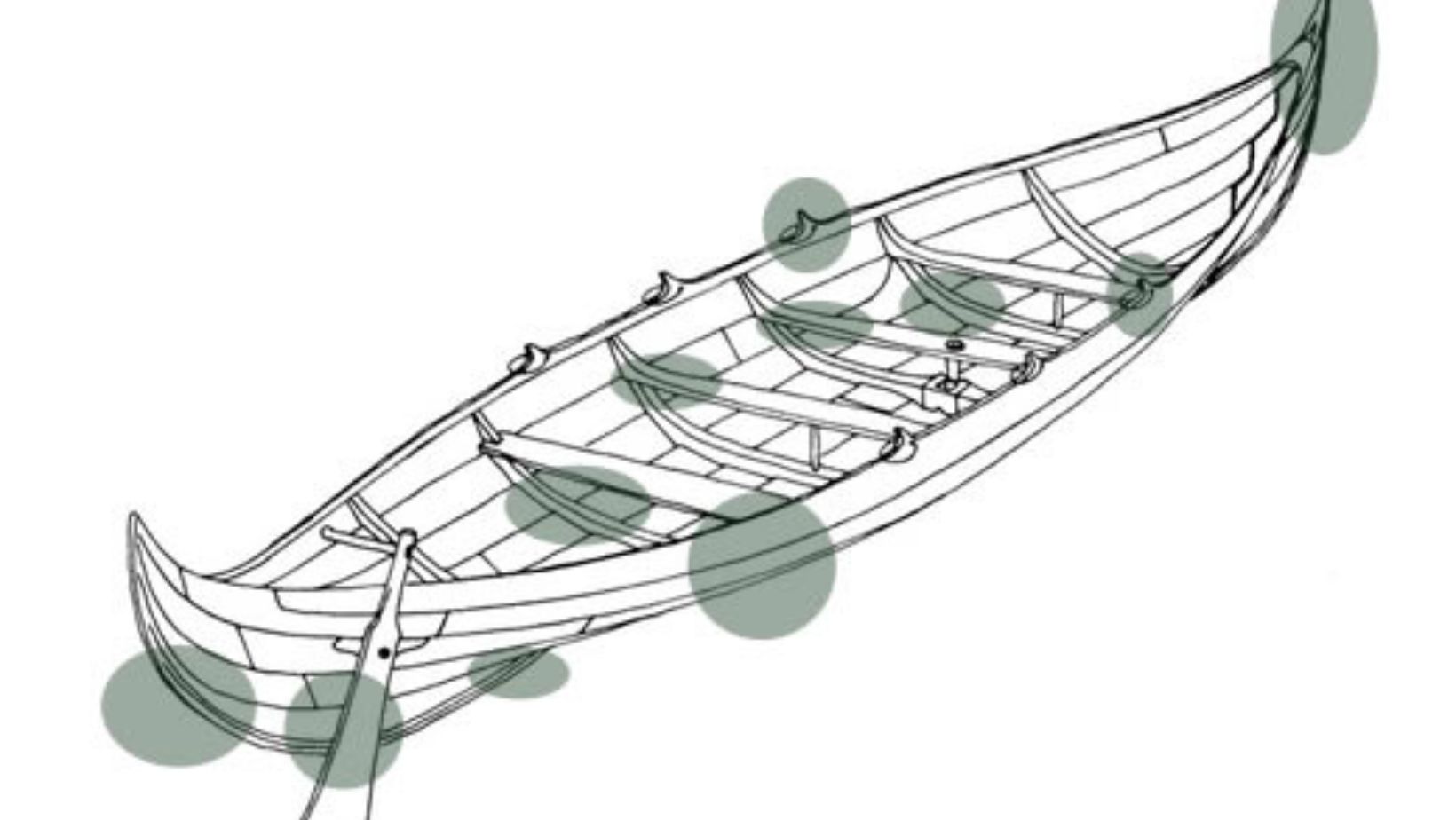

The Keel – Backbone of the Longship

Viking longships were marvels of their time, and it all started with the keel. This sturdy spine was crafted from naturally “V” shaped trees to match its required curve—a clever trick that gave these ships both strength and flexibility on the wild North Sea waves. Think about it: those vessels would be as shaky without this solid backbone as a fish out of water. The keel didn’t just hold things together and helped cut through the water like butter, ensuring Vikings could zip across to the British Isles or even reach down into southern regions at impressive speeds.

And let’s not forget stability. That same design kept the ship steady when sailing sideways against winds—pretty handy in rough northern waters where you’d instead not flip over.

Hull Design – Overlapping Planks for Strength

If the keel was the longship’s backbone, then clinker-built hull planks were its armor. These overlapping planks weren’t slapped together willy-nilly—they followed an intricate pattern that enhanced strength and seaworthiness while allowing them to glide through shallow waters easily.

Clinker construction is like shingles on a roof but way more complex. Each plank overlapped snugly with its neighbor below, creating what we call ‘clinker built.’ Now imagine how secure they had to make these bad boys before setting foot onto open seas. It wasn’t enough to stack them up; nope, they needed something more substantial…enter iron nails. Like rivets in steel beams, each nail was pivotal in holding our seafaring stage together.

At either end sat stern posts rising proudly above the waterline—an iconic silhouette recognizable from miles away—. Still, they weren’t there for show-off points alone (although I bet they got plenty). Stern posts worked hand-in-hand with steering oars controlled by seasoned Viking sailors who knew their craft inside out…

All said and done? A fully assembled Viking longship stood ready as one lean, mean maritime machine capable of facing down everything from spring flowers blooming along riversides to icy breaths off glaciers further north—all thanks largely due in part to these ingeniously simple yet wildly effective designs rooted deep within Norse culture itself.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Viking longships, the legends of the seas, started with a strong keel made from curved trees—essential for slicing through waves and staying stable. Their clinker-built hulls, armored in overlapping planks held tight by iron nails, combined strength with agility. At both ends stood stern posts paired with steering oars that guided these Norse icons across diverse waters.

Crafting Techniques That Defined an Era

Their secret sauce was a unique building method known as clinker construction. This technique involved overlapping wooden planks or ‘strakes’ along a vessel’s hull.

The rounded wooden block wasn’t just any old piece of wood; it had to be strong and supple enough to survive countless voyages across churning seas. Vikings would search for trees with natural curves that matched their ship’s design, using them as strakes attached edge-to-edge by iron nails over a sturdy internal frame.

But what kept these timber titans from leaking like sieves? Enter wool and animal hair – not your typical boat-building materials today but crucial for waterproofing in the Viking Age. Shipwrights would stuff tarred wool into crevices between planks, sealing them tight against even the North Sea’s worst moods.

Oak’s Endurance at Sea – How Were Viking Longships Constructed?

Why oak, you ask? This hardwood could take a beating from waves and warfare while still holding firm. Oak trees provided durable planks that made longships legendary for their longevity and sturdiness on open waters.

Iron Nails – Holding History Together

You can think of iron nails as the unsung heroes keeping everything together under pressure. They fastened those watertight hull planks firmly in place so well that many vessels outlived their owners.

To witness these ancient techniques brought back to life, one needs only visit places like the Viking Ship Museum, where reconstructions based on historic designs showcase how symmetrical halves allowed Vikings to sail efficiently forward—and backward if needed—with bidirectional prowess. It takes more than guts to navigate treacherous waters; it takes cunning craftsmanship refined through generations until mastery becomes second nature.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Viking longships were a marvel, crafted with clinker construction that used overlapping wooden planks fastened by iron nails. Builders chose oak for its toughness and sealed the ships with tarred wool to make them waterproof. This craft wasn’t just about strength; it was intelligent design, allowing Vikings to sail effectively in both directions.

Sailing Mechanics and Maritime Prowess

Ever wonder how the Vikings, with their legendary longships, managed to sail across treacherous seas like they were hopping over spring flowers? It’s all thanks to some pretty nifty sailing mechanics and maritime prowess. Let’s break it down.

Sails and Mast – How Were Viking Longships Constructed?

The mast of a Viking longship could reach up to 16 meters tall—as high as four giraffes stacked on each other. Attached to this towering mast was a sizeable woolen square sail that caught the wind like a giant kite. These sails weren’t just any old piece of fabric; they were woven wool reinforced with leather strips that helped catch even the faintest breeze.

Vikings didn’t have weather apps back then, but they knew how to read those gusty winds. With these powerful sails at full puff, Vikings sailed from chilly Northern Europe to places like the British Isles without breaking much sweat—well apart from rowing when there wasn’t any wind.

Oars and Rudder

Let’s talk about muscle power because sometimes you can’t rely on Mother Nature alone. When winds were playing hard to get or if skimming through shallow waters near shorelines was needed, out came the oars—and lots of them. Depending on where you sat in one of these bad boys determined how long your oar would be, like getting front-row seats versus being stuck behind a pillar at a play.

To steer these wooden beasts around pesky icebergs or into secretive coves for surprise raids (because knocking politely wasn’t their style), Viking ships had what we call steering oars instead of rudders controlled by modern wheels. Imagine maneuvering an SUV using strength and a rope pulley system—it took actual skill.

If only cars today could drift side-to-side as smoothly as those clinker-built hulls with overlapping planks sliced through waves—a technique so good at making sturdy ships that Vikings probably gave themselves hearty pats on stern posts for figuring it out.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Have you ever been in awe of Viking sailors? They were masters at harnessing the wind with their massive woolen sails and knew how to row hard when needed. There is no modern tech for them—just pure skill, muscle power, and a knack for reading the seas like an open book.

Iconography and Cultural Significance

Viking longships weren’t just fearsome vessels of war and canvases showcasing the rich tapestry of Norse artistry. Take the dragon head, often found on prowls—it did more than make a statement. It was steeped in myth, representing protection and power as Vikings set foot across uncharted waters.

The Symbolic Dragon Head – How were Viking longships constructed

The sight of a carved wooden dragon head looming at the front end could send shivers down any foe’s spine—not only because it looked menacing but also due to its deep cultural resonance. The Vikings believed these figures warded off evil spirits, clearing their path for safe voyages through treacherous seas like the North Sea or even out towards far reaches such as L’Anse aux Meadows in North America.

Sailing across long distances demanded physical endurance and psychological strength from Viking sailors. These symbols played into their beliefs—boosting morale among crew members who drew courage from their ship’s protective figurehead when venturing into unknown territories beyond Northern Europe’s familiar shores.

Crafty Learning: Bringing History Home

Inspiring young minds with tales of ancient maritime prowess is one thing; giving them hands-on experience is another level. Crafting miniatures or simple replicas lets kids grasp how every part—from stern posts to those iconic dragon heads—had its purpose and place aboard Viking ships built for both raiding distant lands and navigating through shallow waters around the British Isles or Southern regions during spring flowers bloom.

A family project could involve creating paper mache models adorned with scaled-down versions of ornate decorations seen on famous ships like the Oseberg Ship—a find so significant that it now rests within Norway’s National Museum after being discovered beneath Gokstad mound burial site along with grave goods that narrated stories about those buried there—and Gokstad Ship itself displayed proudly at Oslo’s Viking Ship Museum where visitors can marvel at its grandeur up close.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Viking longships were more than war machines; they carried the Norse culture on their prows, with dragon heads symbolizing protection. Crafting replicas teaches kids this blend of art, mythology, and history.

Preserving History Through Replicas

Imagine sailing across the North Sea like a Viking warrior over a thousand years ago. Modern replicas of famous ships, such as the Oseberg ship burial found in Norway, give us this thrilling peek into ancient seafaring life. These meticulous reconstructions are more than excellent models; they’re vital tools that help experts and enthusiasts sail back in time to grasp Viking craftsmanship and maritime technology.

The Oseberg Ship Burial, discovered within an imposing burial mound filled with fascinating grave goods, stands out as a testament to how Vikings honored their elite. From beautifully woven wool textiles to finely crafted wooden objects, these artifacts offer clues about life during the Viking Age while highlighting Vikings’ deep respect for their sea vessels.

Oak’s Endurance at Sea – How were Viking longships constructed

Vikings relied on sturdy oak planks hewn from mighty trees when building long-lasting ships capable of braving wild waves and winds. The importance of oak is undeniable—it was chosen for its ability to withstand rough conditions on high seas or close encounters along British Isles coasts.

Durable iron nails were indispensable, too; imagine them holding history together by fastening those hull planks tightly so no storm could tear them apart. And don’t forget animal hair mixed with tarred wool—this wasn’t just any old DIY project but essential waterproofing magic that kept sailors dry even when splashed by chilly North Atlantic waters.

Anatomy of a Replica

A faithful replica starts with an authentic keel—the backbone- providing much-needed stability and speed through unforgiving ocean currents around places like L’Anse aux Meadows in Newfoundland, where Vikings set foot before Columbus did.

Clinker-built designs are another genius touch: overlapping hull planks offer extra strength against relentless waves. Even stern posts held secrets—a symmetrical shape meant Vikings could reverse direction without missing a beat (or wave). With square sails patched up from hardy woven wool reinforced by leather strips soaring above deck, it’s easy to see why these vessels ruled over southern regions near France and far-off shores across distant horizons.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Step back in time with modern replicas of Viking longships, and you’ll feel the spray of the North Sea as your ancestors did. These aren’t just excellent models but a hands-on history lesson showing the Vikings’ high-seas mastery.

Oak strength, iron nail toughness, and waterproofing magic were at the heart of these ships. With them, Vikings sailed through storms unscathed and reached lands unknown before others even dared to dream about it.

Every authentic replica whispers secrets from clinker-built hulls to symmetrical stern posts—revealing how ancient shipbuilders quickly conquered familiar coasts and foreign shores.

Longships’ Role Beyond Warfare – Trade & Exploration

Viking longships, renowned for their roles in raids across the British Isles and beyond, were also vessels of economic ambition. These ships sailed far past familiar fjords to bustling foreign ports and even reached the shores of North America at L’Anse aux Meadows. Let’s unravel how these iconic crafts weren’t just about warfare but crucial in trade and exploration.

The Vikings were savvy traders who sought goods from distant lands to bring back home. They loaded their longships with furs, timber, and iron from Northern Europe; then, they set foot on Southern regions where silver coins jingled into their coffers. The ship burials we’ve unearthed tell tales of conquests and commerce—the Gokstad Ship uncovered near Oslo was as much a cargo ship as a raiding vessel.

Navigating treacherous waters like the North Sea demanded maritime prowess that Vikings had honed over generations. Their sailing techniques let them traverse open seas using sturdy oak planks shaped by expert hands guided by experience passed down through countless spring flowers—each bloom marking another season spent building ships.

How Were Viking Longships Constructed?

When imagining these voyages, picture woolen sails billowing above decks lined with shields. At the same time, an imposing dragon head looms at the prow—a symbol known today thanks mainly to replicas displayed proudly at places like the Viking Ship Museum in Oslo.

But what truly stretched Viking influence across continents wasn’t just brawn—it was brains, too. Masterful navigation led them through foggy northern passages to Newfoundland’s L’Anse aux Meadows, proving that daring sea legs could find footing even in uncharted territories thousands of miles away from Scandinavia’s grave mounds adorned with stone ships meant for eternity’s journey.

In essence, those clinker-built hulls stitched together by iron nails carried more than fearsome warriors—they transported ideas, cultures, and innovations across oceans during an age when setting sail often meant never returning home again—or discovering entirely new worlds instead.

Key Takeaway: How Were Viking Longships Constructed?

How were Viking longships constructed? Viking longships were more than war machines; they were crucial for trade and discovery. These sturdy vessels carried Vikings across treacherous seas, reaching distant lands for goods and glory. Their voyages weren’t only about conquest and cultural exchange, shaping an era of exploration.

FAQs in Relation to How Were Viking Longships Constructed

How long does it take to build a Viking longship?

Depending on size and complexity, a skilled crew could craft a longship in mere months, typically less than one year.

How to make a Viking longboat?

Select sturdy oak wood. Use the clinker method for hull planks. Carve ornate designs if desired. Assemble with iron rivets.

What tools did the Vikings use to build their ships?

Vikings used axes for chopping timber, adzes for smoothing planks, augers for drilling holes, and hammers for nailing rivets.

What was the structure of the Viking ships?

Their structures featured overlapping wooden planks (clinker-built), symmetrical shapes with dragon-head prows, and central keels aiding stability at sea.

Conclusion: How Were Viking Longships Constructed?

So, how were Viking longships constructed? They started with sturdy oak. Vikings mastered the clinker method, creating durable vessels ready for rough and shallow waters.

Their asymmetrical shape revolutionized sailing. It made those ships agile on unpredictable waves, allowing reversals without a second thought.

Remember the dragon heads? More than just art, they embodied the Norse spirit and might have scared off more than one foe along their voyages across the North Sea to new lands like North America.

Oars and rudders weren’t mere tools; they symbolized control over vast oceans, making way for legendary explorations that reshaped history.

We’ve unearthed these facts through ship burials like Oseberg’s – grave goods whispering secrets of an era when sea giants ruled waves under spring flowers’ gaze. This is our heritage: marvels of woodwork sailing into eternity from their staging area in ancient Scandinavia to far-flung shores around our globe.